Shipping containers are great tools for warehouses to use, but they can get in the way of your company’s manufacturing processes if not stored correctly. When not in use, workers should take special care to ensure that all containers are stacked properly to avoid safety problems and maintain productivity.

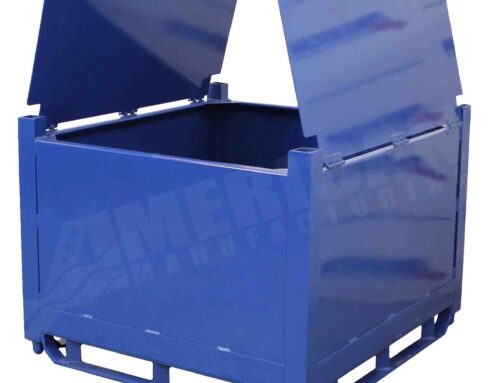

Our heavy-duty steel containers at American Manufacturing can be easily stacked and stored if done correctly. Here are some tips we recommend to ensure your warehouse remains efficient and within proper safety protocols.

Stacking Bulk Shipping Containers

Steel shipping containers offer many uses for your business, including creating a more organized and smarter warehouse setting. When used properly, industrial steel containers offer many benefits, including increased productivity, a safer working environment, and improved storage density.

Automotive bulk shipping containers have several uses, but they mainly transport and store automotive parts and materials. The automotive industry requires heavy-duty storage containers and handling options to maintain a warehouse’s productivity and produce high-quality products.

By stacking your bulk shipping containers, you can take advantage of your warehouse’s vertical storage space, give your tools and parts a designated space, and reduce the time your workers spend doing inventory. Keeping your warehouse’s floor space clear is important for avoiding workplace accidents from dangerous materials, thereby avoiding any injuries that may occur to employees.

Keep Container Bases Level

When stacking bulk shipping containers, it’s important to keep the bases as level as possible. If the bases aren’t level, a stack can fall over, potentially causing an injury to an employee or ruining the product and costing your business money.

Never assume that your container stacks are always perfectly level. Even if containers have been stacked properly, it’s best to take the extra time to inspect each stack’s base to confirm that they are level. If you notice any imbalance, you should rectify it as soon as possible—even if you have to unstack and start over.

Group Similar Shapes and Sizes Together

Always take on a logical approach when stacking shipping containers. Items that are shaped or sized differently will only cause your vertical stacks to look haphazard and random, creating a safety risk and increasing the chances of it falling over and ruining product.

Always group materials with the same size and shape together, allowing for as much uniformity in your stacking as possible. A highly organized container stack is a lot safer for your warehouse and makes it much easier for your employees to retrieve certain items when needed.

Use High-Quality Containers

Most warehouses, especially those in the automotive industry, require heavy-duty containers to store and transport parts. Containers that aren’t of high quality or of poor condition will easily compromise a stack, increasing the risk of it falling over.

Many customers want to spend as little money as possible, so they tend to opt for a thinner gauge of steel when buying shipping containers. Unfortunately, thinner steel is more susceptible to damage, so the trade-off of spending less money may mean putting your merchandise and workers at risk of the container failing when under too much weight from parts.

Always inspect your shipping containers to ensure they have no flaws and are in great condition. Broken containers should be replaced immediately to avoid any materials or parts from being damaged. It’s better for your business to spend extra money on new shipping containers instead of paying for damaged products or workplace injuries.

Avoid Aisles and Emergency Exits

While you may think it’s best to maximize every area of space in your warehouse, there are safety protocols to consider that ensure aisles and emergency exits are always clear of any product. Always limit container stacks to designated areas created for material storage to maintain the ergonomic processes of your warehouse.

While you may think it’s best to maximize every area of space in your warehouse, there are safety protocols to consider that ensure aisles and emergency exits are always clear of any product. Always limit container stacks to designated areas created for material storage to maintain the ergonomic processes of your warehouse.

Aisles and emergency exits are heavily traversed by employees, forklifts, visitors, and others. Not only can stacks topple over into these areas and pose a safety risk, but they can also get in the way of warehouse productivity when employees have to constantly navigate around items to work.

In the case of an emergency, employees must access emergency exits as soon as possible. Any stack in the way will hinder your workers from exiting the building in a timely manner.

Monitor Stacks for Stability

Container stacks must remain upright until any products are retrieved from them. If stacks become too tall, they have less stability and are more likely to cause a workplace injury if they fall. You should regularly monitor your container stacks to ensure they retain their integrity and are stable and sturdy.

If your office happens to be far from the warehouse where you can’t monitor the stacks yourself, you should outsource this responsibility to another employee. This will guarantee that your container stacks remain stable for as long as they need to be. If any stacks appear unstable, they should be taken down and restacked as soon as possible.

Our stackable containers at American Manufacturing will save your warehouse space without decreasing productivity or creating a hazard. With proper stacking practices, your containers will be properly secured, your inventory will remain of high quality, and your employees will have a safer working environment.

As one of the leading steel container manufacturers, American Manufacturing can answer any questions you may have about proper stacking protocol. Contact us at 419-531-9471 or toll-free at 877-LIF-THIS to learn more about our products and production services.

Leave A Comment