Automotive companies rely on shipping containers to safely transport their parts and components from one place to another. Shipping containers are a critical component of any automotive company’s business operations, and it’s important to choose the right type of container for their needs. The two most common types of automotive shipping containers are plastic and steel.

Both plastic and steel containers provide advantages and disadvantages that automotive companies should consider before they make a decision. Which is right for your needs? The answer depends on durability, custom sizing, cost, and environmental impact. Let’s dive in.

Consideration 1: Durability

The most obvious difference between the two materials is durability. Because steel is much more durable than plastic, it can withstand more wear and tear over time without breaking down or becoming damaged. This makes steel containers ideal for long-term storage, as well as for transporting heavy loads. While plastic is lighter in weight, which can be an advantage in transport, it is not as strong or durable as steel and can be easily damaged if not handled correctly. Steel containers can also be stacked higher and more safely than plastic.

Consideration 2: Custom Sizing

Producing a custom-sized container made of plastic can be difficult and costly. However, with steel containers, automotive companies have the benefit of being able to choose quantities and dimensions that perfectly match their needs. Unlike customized plastic containers, steel containers are a cost-effective way to transport bulk materials such as automotive parts while meeting specific size and weight requirements. Plus, with steel, you’ll benefit from additional customized features like dunnageand adjustable levels depending on your needs.

Consideration 3: Cost

The cost of shipping containers also varies depending on the material used. Steel containers tend to be more expensive than plastic; however, they are generally considered worth the investment due to their increased durability and strength. Plastic containers are typically cheaper but may require more frequent replacement due to their shorter lifespan and lack of durability compared to their steel counterparts.

Consideration 4: Environmental Impact

Another factor that automotive companies should consider when choosing between plastic and steel shipping containers is the environmental impact. Steel containers have a lower environmental impact than plastic ones because they are made from recycled materials that can be reused after use instead of ending up in landfills or oceans like plastic can. Additionally, many steel containers are designed with energy efficiency in mind, which helps reduce their overall carbon footprint even further.

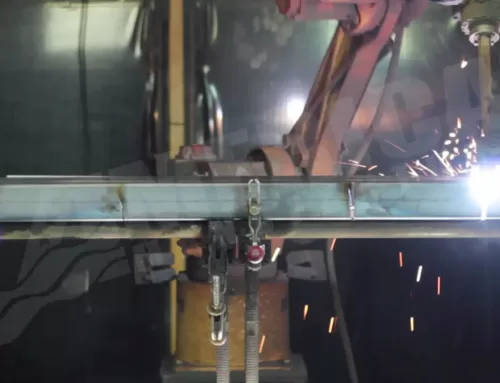

American Manufacturing’s choice: Steel containers

When selecting a shipping container for automotive companies, several factors must be taken into consideration such as weight capacity, size, cost efficiency, insulation capabilities, etc., but perhaps the most important factor is the material used in its construction—plastic or steel?

Both plastic and steel have their pros and cons. It’s just a matter of deciding which one best fits your needs in terms of cost efficiency, durability, capacity, and weight. A little research into each material type can ensure you make the right decision about which container option is right for your company.

At American Manufacturing, we believe in the power of steel. That’s why all of our containers are constructed with the highest grade of this material. Steel offers several advantages over plastic, the foremost being its durability. Our pieces can withstand harsh temperatures and impact much better than their plastic counterparts, ensuring superior performance and longer life overall. What’s more, steel containers are a more affordable option for custom sizing, they stack higher and more safely, and have a lower environmental impact. To learn more about the steel containers produced by American Manufacturing, click here.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Leave A Comment