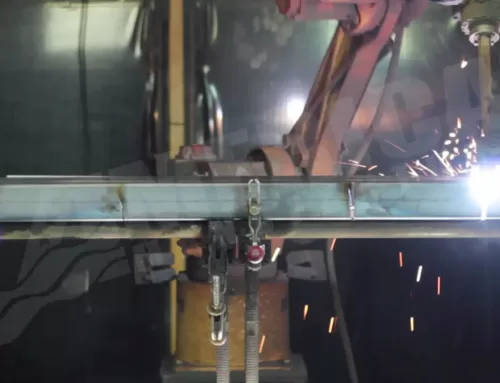

The manufacturing industry is constantly evolving, with technological advancements and innovations. One such innovation, robotic welding, has significantly impacted manufacturing in recent years. Robotic welding involves the fusion of two materials by applying heat and filler material to create a strong bond. Robotic welders are designed to handle and weld parts accurately. By automating this process, manufacturers can improve safety measures, boost production, and minimize the time needed to finish a project.

Here at American Manufacturing, we’ve long recognized the importance of adopting cutting-edge technologies — and we’re nearing our goal of robotically welding an entire container from start to finish. Let’s explore the numerous advantages of robotic welding and how American Manufacturing leverages these benefits to stay ahead of the competition.

Greater Efficiency Through Automation

One key advantage of robotic welding is the ability to increase efficiency in the manufacturing process. Automation reduces the need for a large workforce of skilled welders, resulting in lower labor costs and increased productivity. At American Manufacturing, this translates to a streamlined production process that exceeds client expectations. Furthermore, automated systems are less prone to human error, leading to fewer mistakes and reduced waste in the production process.

Unparalleled Weld Quality and Precision

Robotic welding surpasses manual welding in both quality and precision, ensuring consistent penetration and visually appealing welds. American Manufacturing’s commitment to this technology enables tighter tolerances and products that consistently meet high standards. Additionally, robotic welding produces more durable, stronger welds capable of withstanding rigorous use.

Increased Speed and Throughput

In manufacturing, time is money. Robotic welding significantly increases production speed, helping us meet growing market demands. Robotic systems are tireless and consistent. That level of operation offers unmatched throughput and scalability, allowing us to achieve production goals and adapt to market fluctuations seamlessly.

Consistency and Reliability

Manual welding can be affected by human factors such as fatigue, which may result in inconsistencies in weld quality. In contrast, robotic welding systems provide unwavering consistency, producing uniform welds with minimal variation. With this reliability, American Manufacturing can deliver products that meet our clients’ exact specifications. By eliminating the risks associated with human error, robotic welding also improves safety in the workplace, contributing to a healthier and more secure work environment.

Versatility and Adaptability

Robotic welding systems are not only efficient but also highly versatile. The systems have the capacity to adapt to different needs. And this flexibility allows American Manufacturing to maintain a competitive edge and respond to evolving market demands. In other words, it helps us serve our automotive clients better than ever.

By investing in robotic welding technology, we’re well-positioned to explore new materials and techniques as they emerge, ensuring a future-proof approach to manufacturing. Ultimately, that results in a stronger process, stronger components — and a stronger end product.

Environmental and Economic Benefits

The implementation of robotic welding systems offers environmental and economic benefits as well. These systems contribute to a more sustainable manufacturing process by reducing waste and improving energy efficiency. Furthermore, the increased productivity achieved through robotic welding allows you to remain competitive in the global market, ensuring your long-term success and the continued growth of the domestic manufacturing sector.

Workforce Development and Retraining

As the adoption of robotic welding technology continues, the manufacturing workforce must adapt to new roles and responsibilities. So American Manufacturing is committed to investing in the training and development of our employees, ensuring they are equipped with the skills and knowledge necessary to excel in the rapidly evolving manufacturing landscape. In fact, several American Manufacturing employees are certified with Lincoln Electric’s robotic training program!

The Future of Robotic Welding for Manufacturing

Robotic welding has revolutionized the manufacturing industry, and American Manufacturing is committed to harnessing these advantages for top-tier products on a top-tier timeline. By reducing labor costs, improving weld quality and precision, increasing production speed, ensuring consistency and reliability, and embracing the system’s versatility and adaptability, robotic welding has become an indispensable tool.

Our operators are currently producing a wide variety of robotically welded assemblies and sub-assemblies. And robotics in manufacturing is one of many ways we elevate our products. Contact us today to learn more.

Leave A Comment