Multi-level racks are an excellent product that allows for parts to be transported in an efficient and secure manner. There are multiple uses and benefits to multi-level rack systems that can be implemented within the assembly line and production process seamlessly. Continue reading to learn more about multi-level racks.

What are multi-level racks used for?

Multi-level racks are most commonly used for transporting parts or other goods that need to be protected. Usually, they’re used in the context of stampings and assemblies.They are extremely beneficial for transporting parts that cannot be put into a basket. As multi-level racks do an excellent job of protecting items, they are often used for class A surfaces, which are components of a car that will be seen by the customer once installed. In short, these parts cannot incur any damage during transport, so the multi-level rack is used to protect them via custom dunnage systems.

It is also important to keep in mind the size and height of a multi-level rack. The multiple shelves allow for a shorter rack without compromising the pack density. This enables you to stack more product within a truck than is possible with a single level rack. This leads to fuel and transportation savings.

How do multi-level racks work?

When unloading multi-level racks, they prove useful due to their swinging shelf. The middle shelf is able to be out of the way, so it makes unloading the bottom much easier. It is also possible to build racks taller so more goods can be stacked on a single truck. Not only is unloading easier but fitting more parts into one rack and therefore onto one truck is extremely advantageous.

Who uses multi-level racks?

Due to the numerous benefits that multi-level racks offer, they are generally utilized by OEMs such as Ford or Chrysler, but they could be helpful for anyone that does sequencing. As the racks stack on top of themselves, they help keep things from moving and also keeps things safe by creating a storage cell. In addition to OEMs, industries and manufacturers in the truck and trailer industry outside of automotive could also benefit from using multi-level racks. Different companies that are going to assemble a product that has many separate parts or components could benefit from using a multi-level rack because of the ability to securely put many parts into one rack.

Products similar to a multi-level rack

While multi-level racks are incredibly useful and secure, when shopping around, many customers often wonder if there are other products that are similar to a multi-level rack that they should also consider purchasing. While there isn’t necessarily one replacement, some buyers do consider bag racks for a cheaper and simpler option. Bag racks can support some of the needs that customers have; however, before deciding on one product over another, we would encourage you to reach out to us. This enables you to talk with one of our experts about your specific products, transportation methods, and assembly lines, and we’d be glad to help you select the best item for your transportation needs.

The benefit of American Manufacturing Multi-Level Racks

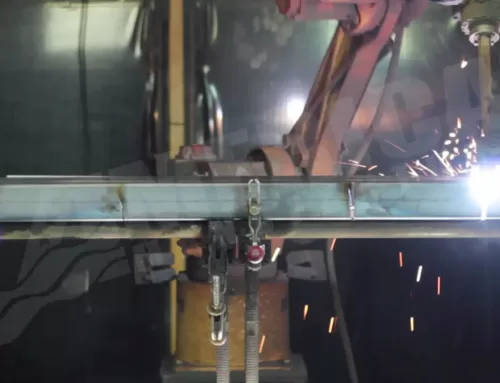

Our customers find excellent benefits from the American Manufacturing multi-level racks. The most advantageous aspect of our multi-level rack is the ease of use offered. Not to mention, they are extremely high quality, and we also are proud to offer an excellent turnaround time from the moment of purchase. We are a fast producer of standard shipping racks coupled with a high-quality design. The use of aidedshocks and pistons give lift assistance to the operator while using the rack.

Don’t hesitate to contact us today to discuss our multi-level racks. We look forward to assisting you.

Leave A Comment