When working in a warehouse or ordering products, choosing the correct equipment should be a straightforward experience that lets you know what you’re getting. However, not all equipment terms are universally defined, which can lead to confusion. “Pallet” and “Skid” are terms used interchangeably when it comes to transportation and storage. Both can perform similar functions depending on the task, but understanding the difference between the two, including the complete picture of the pros and cons of skids vs. pallets, is essential for using either tool effectively and for the proper purposes.

Here’s how the two are differentiated: Pallets have both a top and bottom deck, whereas skids have only a top deck with no bottom level or boards. Generally, this makes skids more moveable than pallets but less robust overall. This design qualifies why each is made for distinct purposes.

What Is a Pallet? And when should I use one?

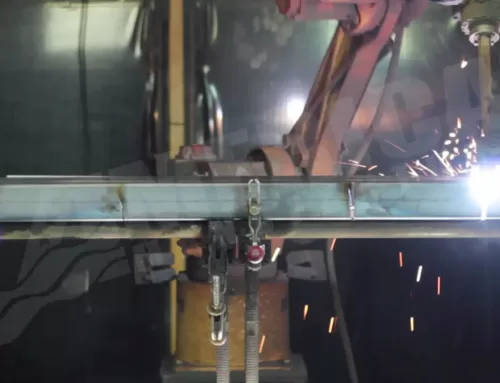

This flat structure with a top and bottom deck is made of three to four stringers connecting the deck boards. The pallet dimensions usually have a surface area of 48” by 40.” Wooden or plastic pallets often have a weight limit of up to 2200 lbs or approximately 1000kg; however, metal pallets, including industrial steel pallets, can dwarf this restriction, holding up to 4000 lbs or 1800 kgs. American Manufacturing makes steel pallets used for battery trays, stamping blanks, and other automotive-related products for traditional fuel vehicles as well as EVs.

The structure of a pallet means that they are an appropriate choice for heavier items. This also means that due to its heavy base of support and a large amount of friction, loaded pallets, including small pallets, usually are only moved by a forklift as they are extremely difficult to drag. This is where skids come in.

What Is a Skid? And when should I use one?

A skid is similar to a pallet but designed without the bottom deck. Like a pallet, a skid has 48” by 40” surface dimensions, but its weight limit is restricted to individual supplier restrictions, and likely holds significantly less weight than the more fortified pallet. The absence of the bottom deck also means that a skid is far more mobile than a pallet and, therefore, can be used to drag or “skid” items from one place to another. Even though the skid can generally hold less weight than a pallet, it is often a popular option to use as a foundation for heavy machines, should they need to be moved.

Additionally, the other application of the skid’s non-existent bottom deck means that it’s easier to use with a pallet jack for more effortless mobility in areas where forklifts are not allowed.

Our steel “skid” made with a corrugated deck and two-way fork access has the moveable benefits of a skid but with a static capacity weight restriction of up to 4000 lb, making it incredibly sturdy and reliable. This means that choosing our skid provides a solid choice for those looking for a mobile skid that also outperforms competitors regarding weight limit and versatility.

Choosing Pallets vs. Skids

Both items have distinct purposes and should be considered and treated as such. While a skid is cheaper than a pallet, it’s important to know that this is the more mobile choice that should be used for items that need to be moved and not for any item that breaks the weight limitation.

Pallets are more expensive than skids but should be the go-to choice for items that require stability, are heavier, and can only be hauled with a forklift truck (and consequently not useful for items that need to be manually or frequently moved around.)

While skids were one the most popular type of pallets in the industry, most would now consider modern steel pallets as a preferable equipment choice for storage, loading, or unloading, especially with widespread access to forklift transportation.

Want to stay up to date with the latest products in manufacturing? Want to know more about our steel pallets for sale? Or are you simply looking for ways to streamline your daily operations or transportation? Understand what materials you need to get your job done right by checking in with American Manufacturing and all the products we offer.

Leave A Comment