Tilt dollies are a key aspect of the efficient maneuvering of parts within a warehouse. They are extremely safe and useful dollies as they can move up to 2,000 pounds depending on the style of tilt dolly. Typically, tilt dollies are found in the automotive setting and are a reliable part of an assembly line.

What Is a Tilt Dolly?

A tilt dolly is different from a dolly one might expect to see within a moving setting. Tilt dollies are used within production and can be useful for keeping forklifts out of the warehouse. Tilt dollies, as their name suggests, are used to quite simply tilt parts towards people. However, as straightforward as this may seem, their benefits and uses should not be underestimated. Additionally, the quality of a tilt dolly resides much in its features and the material it is made up of.

Benefits of a Tilt Dolly

While there are a variety of benefits to tilt dollies, the two most prominent are that they create a safer environment, and they increase the efficiency of production.

Safety

Tilt dollies make warehouses safer in two main ways. First, they help protect the operator from injury or strain due to lifting heavy parts over their head or bending down to retrieve parts. This process, especially when repeated, can become harmful for an employee because if their posture fluctuates, they could be easily injured. Preventing such motions is critical for their safety and overall well-being.

The greatest way to protect employees’ safety is to aid them in their efforts and limit strain. This makes the process of moving parts much lower stakes and employers, and employees alike can have peace of mind that they are implementing best practices within their warehouse and manufacturing process.

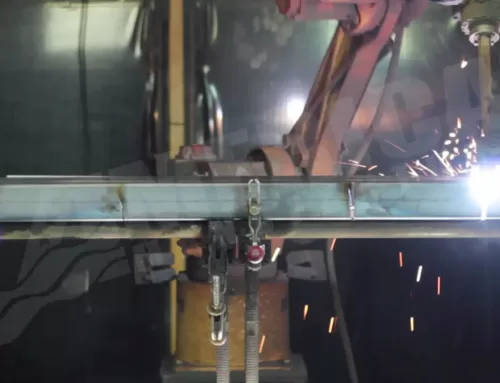

A tilt dolly also brings safety to the workplace or manufacturing environment by enabling the environment to go forklift-free. Tilt dollies can be used easily with a tugger which has no mast (like a forklift) or vision obstruction to the driver. The tugger operator can hook up to the draw bar and pull away with a loaded train of dollies without having to disengage every dolly’s brake without automatic break release mechanism. This system saves the driver time and helps to facilitate the production process. In addition, the coupler, which is used when dollies are chained together, allows them to be trailered and released via a foot release keeping the operators hands away from any potential pinch points. These releases can happen in the middle of a train of dollies, giving the operator more flexibility while supplying kitting or sequencing stations. Additionally, tilt dollies are useful for those attempting to get a product into a tilted, ergonomic position where they are able to move the product into a cell and tilt to an operator. The tilt dollies are hydraulically assisted by our tilt cylinder which keeps the tilting load at a slow and steady pace until it reaches its tilted position. The makes sure that the operator does not need to assist the dolly while it is tilting a container.

Efficiency

The manufacturing process relies heavily on efficiency, making it important for warehouses to prioritize this capability of a tilt dolly. The efficiency of tilt dollies can be seen through the amount of material they’re able to move at one time. A bulkier caster, such as the eight-inch caster we use at American Manufacturing, provides the ability to have a higher load rating combined with our higher durometer rating. This means that the tilt dolly has a much lower initial push-pull force or amount of force in pounds that it takes an operator to move the dolly from a resting position. We are able to keep our push-pull force at about 45 pounds.

When would an operator not want to use a tilt dolly?

While tilt dollies are extremely useful and safe, there are situations in which you would not want to use one. This could happen if one uses a very tall container or rack as those can be problematic in certain situations. For taller containers and racks, a lowboy or static cart is likely a better option. In addition, if a manufacturing line was using a bag rack, the better option would be to pair it with a rotate cart. Another situation would be if your combined weight needed to be tilted is over 1,500 pounds. With higher weights, we would suggest using our ergonomic equipment. These monument structures are safer for higher weight ratings. Overall, tilt dollies are typically used for containers and function best with such use.

Tilt Dolly Options at American Manufacturing

At American Manufacturing, we strive to consistently provide quality dollies for all of our customers. Our heavy-duty dolly is a product that is used with heavier weight ratings. Through the use of our counterweight and foot pedal system, operators can easily tilt and return the cart to its neutral position. We can produce tilt dollies of 30, 45, and 60 degrees of tilt that have the capability to tilt either forward or sideways. Additionally, the JE Lowboy Tilt Cart, one of our newer products, is a tilt dolly that may want to be considered. The Lowboy allows for a lower neutral position while still getting to 30 and 45 degrees of tilt.

At American Manufacturing, we are proud to support a variety of needs with our tilt dollies. We focus on high-quality materials and would be glad to help you with your tilt-dolly selection. Contact us today for more information.

Leave A Comment