Advancement and sustainability go hand-in-hand when it comes to the future of manufacturing. As the industry continues to explore new technologies and consider different ways to cut back on wasteful practices and amp up productivity, sustainability is the natural byproduct.

Advancing sustainable manufacturing practices includes everything from increasing energy efficiency to utilizing more sustainable materials, but ultimately it comes down to the impact of technology on manufacturing’s potential for sustainability.

Why Sustainable Manufacturing Practices Matter

As manufacturing shifts away from traditional models and embraces innovations and technologies, sustainability is the name of the game. Consumers are increasingly interested in shopping sustainably, and manufacturing regulations and standards are beginning to reflect this mindset as well.

It is more important than ever that manufacturers are attentive to their carbon footprints with the urgency surrounding climate change. This need for sustainability in manufacturing extends to businesses of all sizes and industries, not just the larger corporations. Every manufacturer can affect climate change by investing time and resources in sustainable manufacturing practices for a better future.

The Future of Sustainability in Manufacturing

When it comes to advancing sustainable manufacturing practices, much of this comes from innovative technologies to improve efficiency and reduce waste. With the “Internet of Things” (IoT) y increasing productivity and improving quality across all manner of manufacturing-related industries, advancements in sustainability are directly linked to advancements in technology,

However, advancements in sustainable manufacturing don’t start and end with the latest technology. Every aspect of the manufacturing process can be adapted and improved for more ethical and sustainable practices. Here are four areas where we see sustainable manufacturing practices advancing as we move toward a better, brighter future for our industry and our planet.

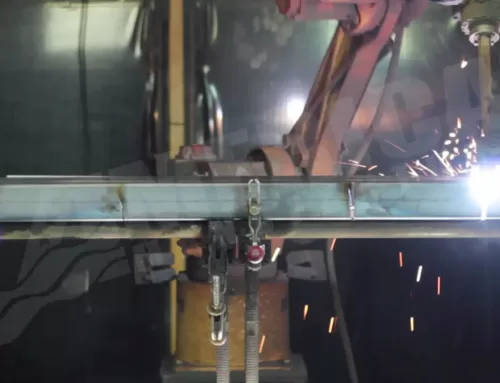

1. Robotics and Automation

While it is not the be-all and end-all of sustainable manufacturing, technological advancements play a significant role that shouldn’t be overlooked! In fact, the United States Environmental Protection Agency (EPA) lists technologies as one of the best ways to reduce emissions in the industrial sector.

A lot of what makes using robotics and automation in manufacturing sustainable is the reduction of waste. Automated manufacturing processes speed up production significantly and decrease the risk of human error, especially in high-volume manufacturing. These decreased cycle times and increases in efficiency mean significantly less energy output, allowing manufacturers to increase product volume without increasing their carbon footprint.

2. Sustainable Packaging and Storage

The most visibly sustainable element of manufacturing for consumers is the packaging itself. Customers who are attentive to the eco-friendliness of businesses they support will often note whether the packaging is sustainable, usually through being recyclable. The use of more sustainable packaging where practical is how many manufacturers publicly demonstrate their commitment to reducing their carbon footprint.

Strategically storing and organizing products is also a major contributor to advancing sustainability in manufacturing. A warehouse that is organized and streamlined to reduce waste and consumption will not only be more sustainable but will also be more efficient.

3. Nanotechnology

Nanotechnology—and more specifically, nanomanufacturing—allows companies to greatly decrease energy consumption while improving manufacturing processes. Nanotechnology has led to noteworthy breakthroughs in manufacturing, such as additive manufacturing (or 3-D printing) and generative design.

Because these tools enable manufacturers to develop and design new products and technologies flexibly and virtually, they make it possible for new ideas to be explored without wasting materials or expending excess energy and resources on innovation.

American Manufacturing is Committed to Sustainability in Manufacturing

At American Manufacturing, we’re a company that believes in the power of innovation and advancement, for the sustainability it brings along with other benefits like reduced lead times, decreased costs and improved product quality. Our manufacturing processes are heavily automated and supported by technological advancements such as robotic welding machines and, more recently, cobots.

Contact us to learn more about how our advancements in sustainable manufacturing practices can support your custom manufacturing needs!

Leave A Comment