In an era so focused on automation, technology, and constant improvement by digital means, manufacturers need to be at the forefront of any digital trends transforming the way products are built. Here is what we’re seeing transform manufacturing today and what has us excited for the future, whether it be on an industry scale or within our own assembly department.

New Trends We’re Seeing in Manufacturing

Technology is foundational to high-quality manufacturing, and the trends are very supportive of this ideal. All of the trends that we are investing in or excited about come from new ways of doing things through creating better and better equipment to support manufacturing processes. Here are our top five manufacturing innovations going into 2024:

1. Laser Cutting vs. HD Plasma Cutting

HD plasma cutting has been the victor in robotic cutting for many years. It’s cheaper than laser cutting and generally more effective for thicker material cutting. However, many manufacturers are moving away from plasma cutting and toward faster and more versatile fiber optic lasers.

These lasers are masters at creating fine, intricate cuts while manipulating the most fragile of materials. Everything from glass and ceramics to the metals we cut at American Manufacturing for automotive parts and racks relies on the precision and delicate touch of a fiber optic laser. Plasma cutting may not be completely phased out yet, but as laser cutting continues to improve, this technology may one day overtake its predecessor.

2. Robotic Bending Cells

This is one manufacturing trend we can’t wait to explore for our builds! We’ve been watching robotic bending cells start to crop up in manufacturing for the last few years, but until recently they haven’t been able to do what we require. With so many integrators using robotic bending cells these days, their functionality has grown and we may be seeing some of these in our robotics fleet one day soon!

3. Tube Lasers

Flat sheet lasering is best complimented by a 3D tube laser. A typical flat sheet laser is only able to cut sheet steel —usually no more than ten feet depending on the size of the laser bed. Tube lasers can handle everything else like angle iron, channel, bar stock, pipe and of course tube up to twenty feet or more at one time! This is because tube lasers move and shift the material throughout the process, rather than cutting a static material placed on a flat surface.

What has us so excited about tube lasers is the amount of automation. Once you load the material into the magazine, it runs itself! This is a huge benefit in an industry that is still struggling with a shortage of skilled workers.

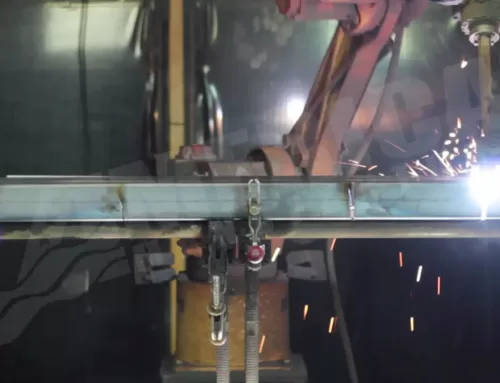

4. Cobots

It should come as no surprise that cobots are making waves in manufacturing. These inexpensive and powerful machines have been the perfect addition to our welding team with their built-in safety features and flexible programming. When it comes to embracing innovative technologies for the goal of cutting costs, nothing quite compares to the cobot.

5. Robotic Painting

Robotic painting is an up-and-coming tool for speeding up finishing processes and improving manufacturing quality for final products. While we haven’t explored this technology yet at American Manufacturing, we’re very excited about the possibilities.

What These Trends Mean for Our Customers

Trends may be fun to read about and research, but what do they actually mean for our customers? Whether we use plasma or fiber optic lasers, or flat sheet & tube lasers, how do our processes and technology impact you?

The most obvious benefit is time. Thanks to greater automation in our manufacturing processes, we can offer reduced lead times and offer a much faster turnaround to our customers of both high-volume and small, prototype orders.

These digital transformations also empower us to more efficiently pivot between orders. If a customer needs a prototype when we’re busy running a large order, our technology makes it possible—and easy—for us to shift directions and form or cut the prototype’s parts. Again, this means faster turnaround times without sacrificing the quality of the product. In fact, our quality has only improved since introducing cobots and other innovative equipment to our workforce!

In Manufacturing, It’s All About the Trends!

Trends may flare up and die quickly in some industries, but when it comes to manufacturing the trends are what make or break you. A manufacturer who isn’t willing to change and grow will just stagnate. The quality, cost and speed of production can never improve if the manufacturer is clinging to outdated methods and equipment! This is why we’re so passionate about constantly upgrading and testing out new methods of manufacturing. When you pick an innovation-based manufacturer like American Manufacturing, you can trust that you are always getting the very best results. Contact us to learn more about how our technology can build exactly what you’re looking for.

Leave A Comment